Quick-Change Chuck: One Person, One Push, Two Rotations – Efficiency Boost of 70%!

In industrial production lines, the efficiency of equipment installation and changeover directly impacts the continuity and economic benefits of the entire production process. Traditional multi-hole alignment methods are not only cumbersome but also require multi-person collaboration, posing significant safety risks, especially in elevated work environments. The Centron dispensing machine quick-change chuck provides an innovative solution to this challenge .

01 Simplified Installation Process: One Push into Position, Automatic Alignment

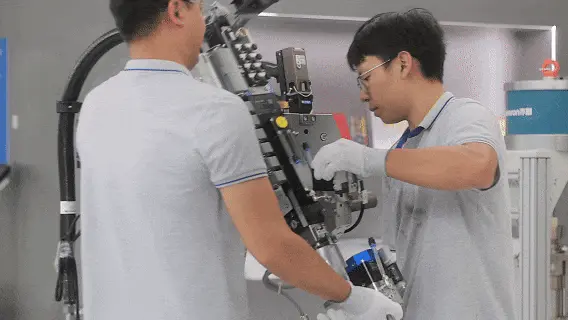

The core advantage of the Centron quick-change chuck lies in significantly simplifying the installation process. Operators simply pre-install the chuck components on the bracket and dispensing machine. During elevated work, a single person can gently push the equipment into the slot. The unique positioning block design enables automatic alignment, completely eliminating the tedious traditional multi-hole alignment process. This greatly reduces labor requirements and operational difficulty, while also significantly lowering the risks associated with multi-person collaboration in elevated work .

02 Efficient Fixation Method: Two Rotations to Secure, Stable and Reliable

In terms of fixation efficiency, the Centron quick-change chuck requires only the tightening of the top two positioning screws to complete fixation, avoiding the cumbersome process of traditional multi-hole alignment. This design not only reduces operation time but also improves the stability and consistency of the connection, providing strong assurance for production process reliability .

03 Convenient Maintenance Design: Angled Removal for Efficient Maintenance

When equipment requires maintenance, operators need only loosen the two screws and the fixing block, then remove the equipment along the chuck slot at an angle, without complex procedures. This design significantly shortens the time required for equipment maintenance, enhances the overall operational efficiency of the production line, and makes equipment maintenance convenient and efficient .

04 Outstanding Performance: 70% Efficiency Improvement, Wide Compatibility

Practical applications demonstrate that the rapid separation design of the Centron quick-change chuck improves equipment changeover efficiency by over 70%, drastically reducing downtime and effectively ensuring production line continuity. Furthermore, the product offers excellent compatibility, adaptable to various dispensing machine models such as 100cc, 200cc, and 450cc, supporting flexible switching and optimal configuration of production lines .

The Centron dispensing machine quick-change chuck, through its innovative design, addresses multiple pain points in traditional equipment installation, achieving a dual enhancement of efficiency and safety. In the era of Industry 4.0, such innovative designs focusing on practicality and efficiency will provide strong support for enterprises to improve production efficiency and reduce operating costs. As manufacturing demands for production efficiency continue to rise, these intelligent and user-friendly equipment accessories will find applications in more fields, injecting new vitality into the transformation and upgrading of manufacturing .