How to Choose Screw Dispensing Equipment? Micro-Precision Metering is the Core!

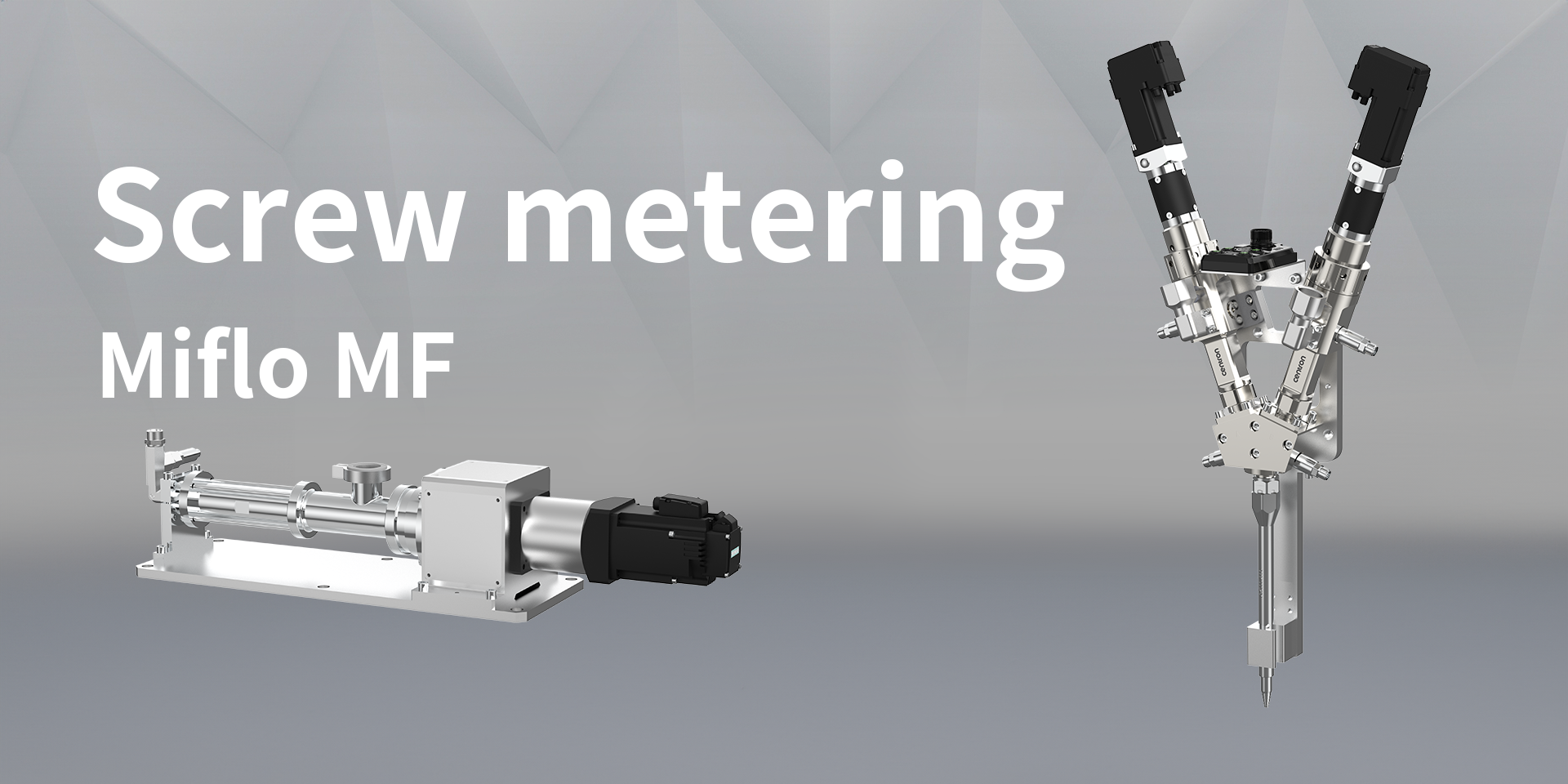

In precision processes such as dispensing for 3C electronic chips, adhesive application for power battery components, and potting for photovoltaic junction boxes, even minor deviations in adhesive volume can lead to product failure. As the core equipment for achieving micro-dispensing, the key selection criteria for screw dispensing equipment consistently revolve around "micro-precision metering." So, how should one choose screw dispensing equipment? The answer is clear: start from dimensions such as metering accuracy, compatibility, and control synergy to find equipment that meets the industry's need for micro-dispensing. Centron's Miflo series screw metering system is a typical representative in this field .

I. First, Consider the Core Metric: Does the Metering Accuracy Meet Industry Requirements?When selecting screw dispensing equipment, the primary focus should be on metering accuracy—the foundation for determining whether micro-dispensing meets standards. The metering accuracy of Centron's screw dispensing equipment (Miflo series) reaches ±1%, with a minimum discharge volume as low as 0.014ml. Such parameters can precisely adapt to the micro-demand requirements of various industries : for instance, in semiconductor chip dispensing in the 3C electronics field, where adhesive demand is extremely low and tolerance for deviation is minimal, ±1% accuracy can prevent chip short circuits caused by excess adhesive or sealing failure due to insufficient adhesive volume; for thermal conductive adhesive application in power battery components, a minimum discharge of 0.014ml meets the precise application needs between components, ensuring uniform thermal performance and avoiding local overheating risks. Even if industry requirements for micro-precision are slightly lower, it is essential to ensure that the equipment's accuracy error does not exceed the process allowable range; otherwise, numerous defects may occur in production, increasing costs .II. Next, Assess Compatibility: Can It Cover Material and Process Scenarios?Even with high metering accuracy, screw dispensing equipment cannot function effectively if it cannot adapt to the material characteristics and process scenarios in production. In terms of material compatibility, Centron's screw dispensing equipment supports adhesives, thermal materials, and sealing materials ranging from low to high viscosity. It can even handle materials containing large particles. Additionally, it can be optionally equipped with DuraTec wear-resistant technology and highly corrosion-resistant stator materials to adapt to highly filled and abrasive materials (e.g., thermal paste with 9W conductivity), extending the equipment's service life in special material scenarios . For example, for low-viscosity potting compounds commonly used in photovoltaic junction box potting, this equipment can reduce adhesive wall hanging and residue, ensuring metering accuracy. For stator dipping varnish processes in automotive motor controls, which involve particle-containing paints, the equipment can also ensure stable delivery without affecting precision .In terms of process scenario adaptation, Centron's screw dispensing equipment can cover both single-component and dual-component applications: single-component scenarios are suitable for structural bonding in motor controls and LED sealing in 3C electronics; dual-component scenarios focus on application for power battery components and modules, supporting a mixing ratio range of 2:1 to 8:1, meeting the metering needs of different two-part materials . When selecting screw dispensing equipment, it is necessary to confirm the equipment's compatible viscosity range, compatibility with special materials, and whether it can cover one's own process types to avoid the problem of "parameters meeting standards but scenarios being incompatible" .III. Not to Be Overlooked: Can the Control System Ensure Metering Stability?The micro-precision metering of screw dispensing equipment relies on the synergistic support of the control system—even if the equipment itself meets accuracy standards, metering fluctuations may occur if the control system responds slowly or has poor adaptability. Centron's screw dispensing equipment is paired with its independently developed CS3000-MF control system, which has a program scanning cycle as low as 1ms, enabling rapid response to dispensing parameter adjustments, reducing adhesive pattern fluctuations, and ensuring accuracy stability during micro-dispensing . It also supports 4 industrial bus protocols, facilitating integration with mainstream industrial equipment and meeting the integration needs of automated production lines .Furthermore, this control system also has two major advantages: First, it supports storing 255 independent recipes. For multi-variety, small-batch production, quickly adapting dispensing parameters for different products only requires switching recipes, eliminating frequent hardware adjustments and indirectly ensuring metering consistency . Second, it features an adaptive control function that can self-learn changes in adhesive viscosity and adjust metering parameters in real-time, maintaining ±1% accuracy even if material viscosity fluctuates slightly due to environmental factors like temperature . When choosing screw dispensing equipment, pay attention to the response speed, recipe storage capacity, and adaptive adjustment functions of the supporting control system, as these are key to maintaining metering stability in long-term production .IV. Supplementary Details: Can Installation, Maintenance, and Service Reduce Subsequent Costs?The long-term stable operation of screw dispensing equipment also requires consideration of ease of installation and maintenance and service support. Otherwise, production efficiency and metering accuracy could be affected by complex maintenance or slow fault response. Centron's screw dispensing equipment features an advanced structural design for easy installation and routine maintenance. Unique sealing and lubrication technologies can reduce maintenance costs . It also comes equipped with pressure detection and torque detection functions, allowing real-time monitoring of the equipment's operating status and early detection of abnormalities that might affect metering accuracy .In terms of service, Centron has built a global service network, including 12 domestic service stations and 7 spare parts warehouses within the country, and overseas service stations in Italy and Thailand along with a spare parts warehouse in Hungary. They offer telephone technical support within 2 hours and on-site engineer service within 24 hours during the warranty period, enabling quick resolution of equipment faults and reducing unplanned downtime . When selecting screw dispensing equipment, these details, while not directly determining metering accuracy, can impact the long-term cost of use and accuracy stability, and thus require comprehensive consideration .Anchor on Micro-Precision Metering to Choose the Right Screw Dispensing EquipmentHow to choose screw dispensing equipment? The core logic is "anchoring on micro-precision metering, while balancing compatibility, control synergy, and maintenance service." Judging from the design of Centron's screw dispensing equipment, whether it's the ±1% metering accuracy, multi-scenario material compatibility, or deep synergy with the CS3000-MF control system, everything revolves around the core of "micro-precision." It meets the precision dispensing needs of industries like 3C electronics, power batteries, and photovoltaics . For enterprises, choosing the right screw dispensing equipment can not only guarantee product quality but also enhance production efficiency, laying a foundation for gaining an advantage in high-end manufacturing competition.